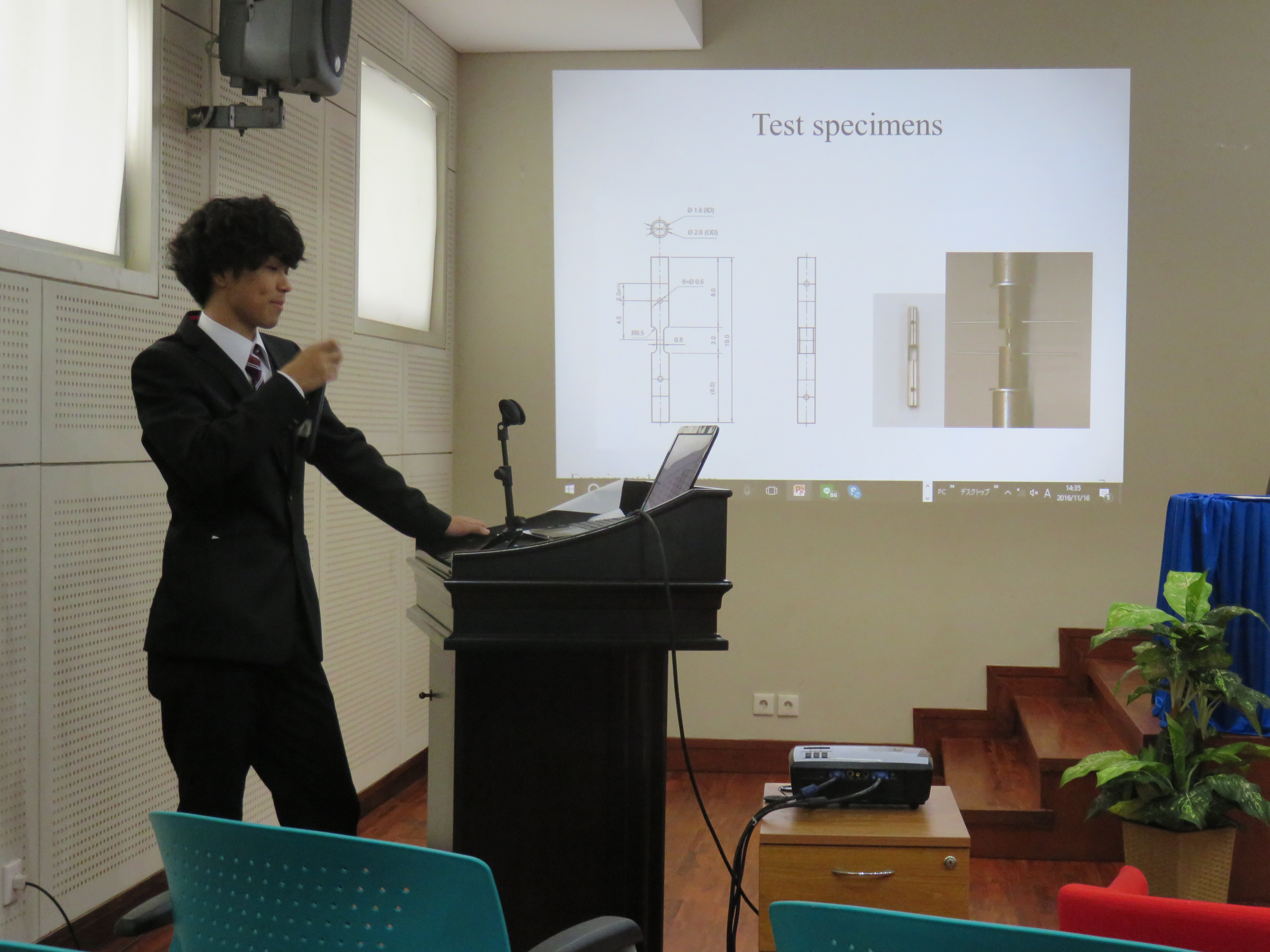

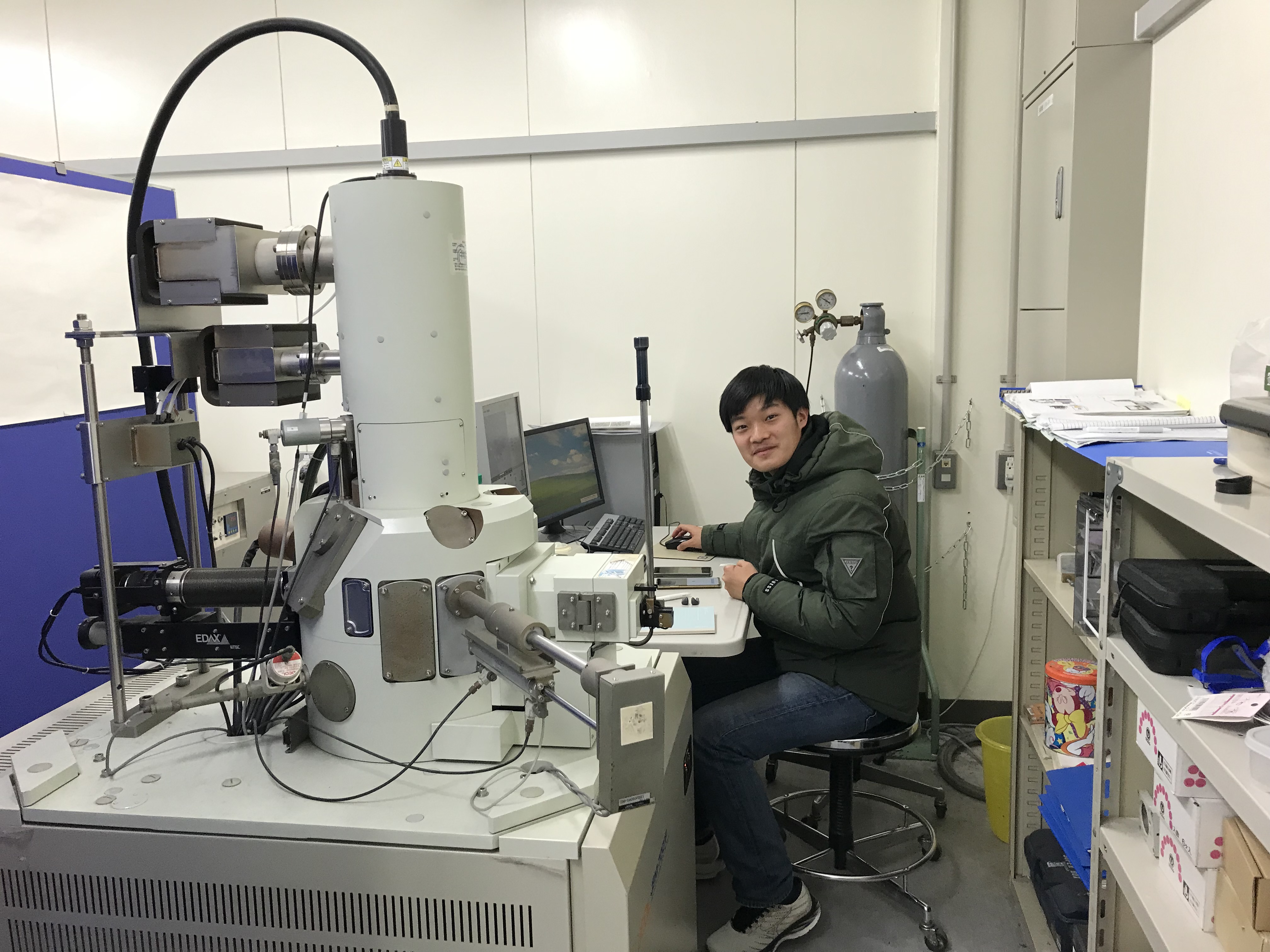

Our Research Group

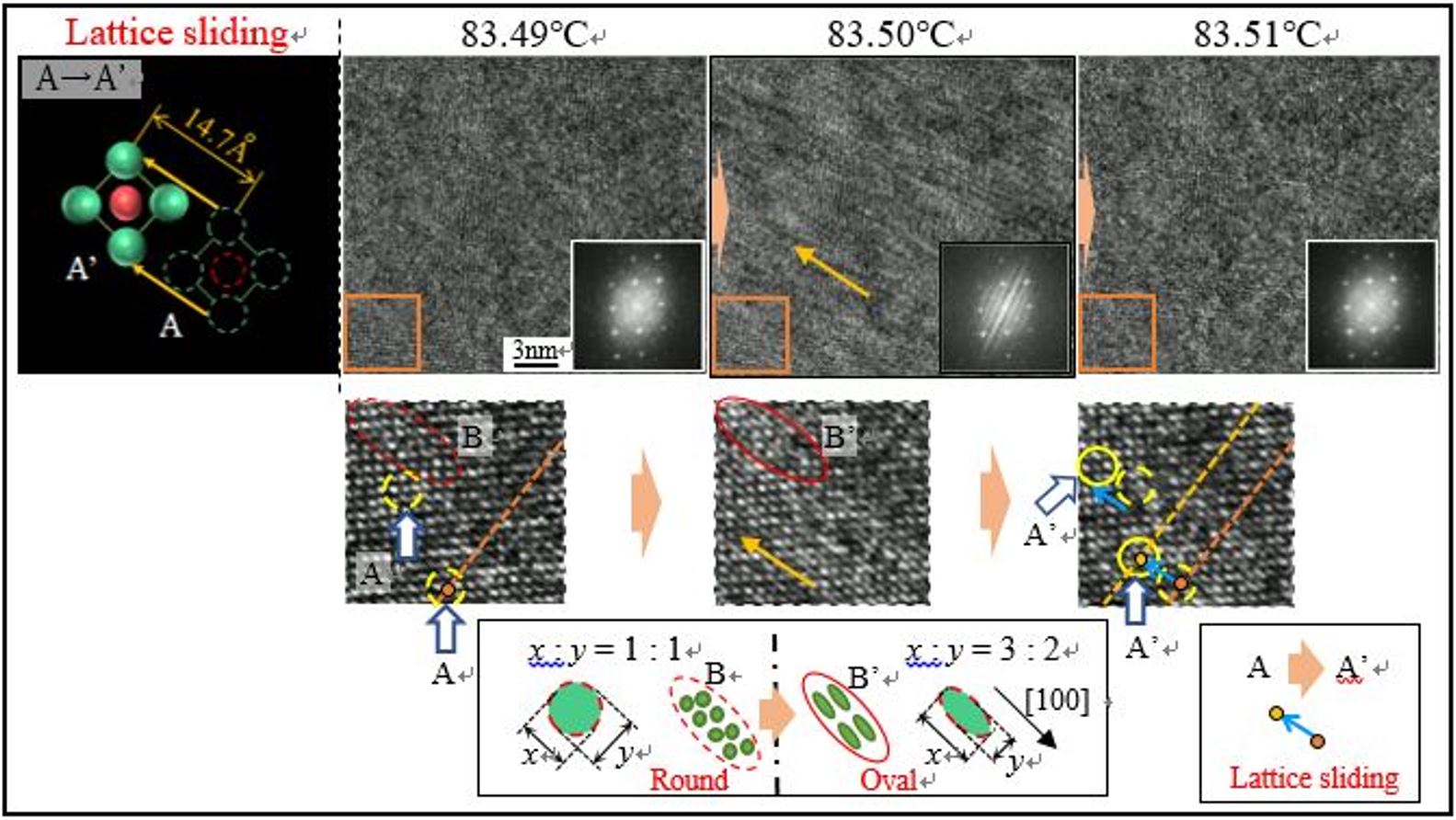

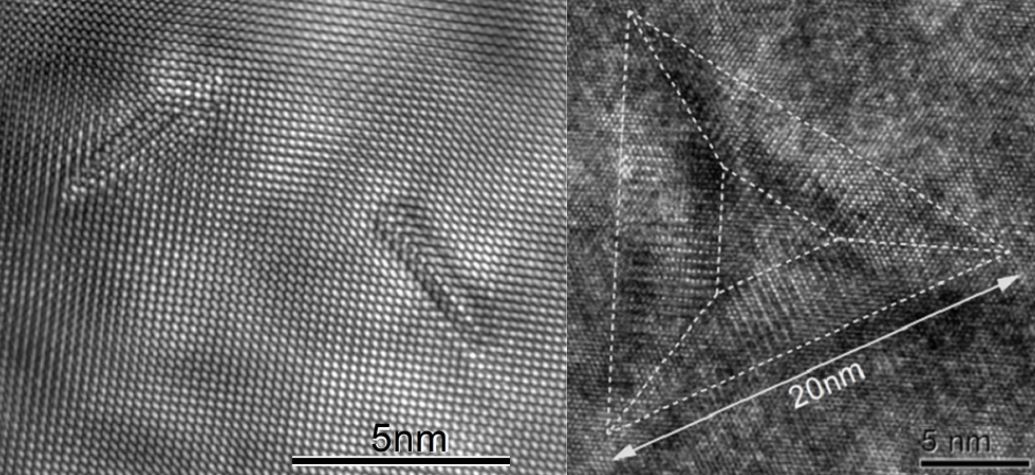

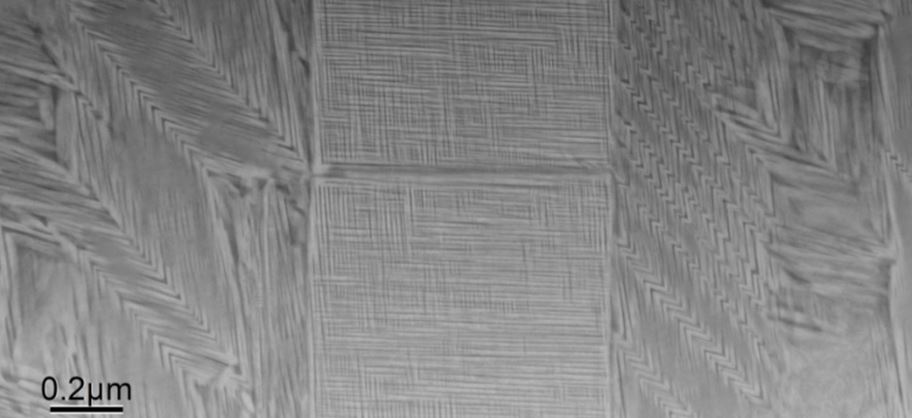

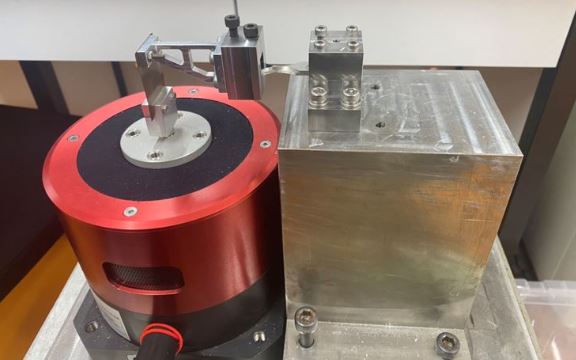

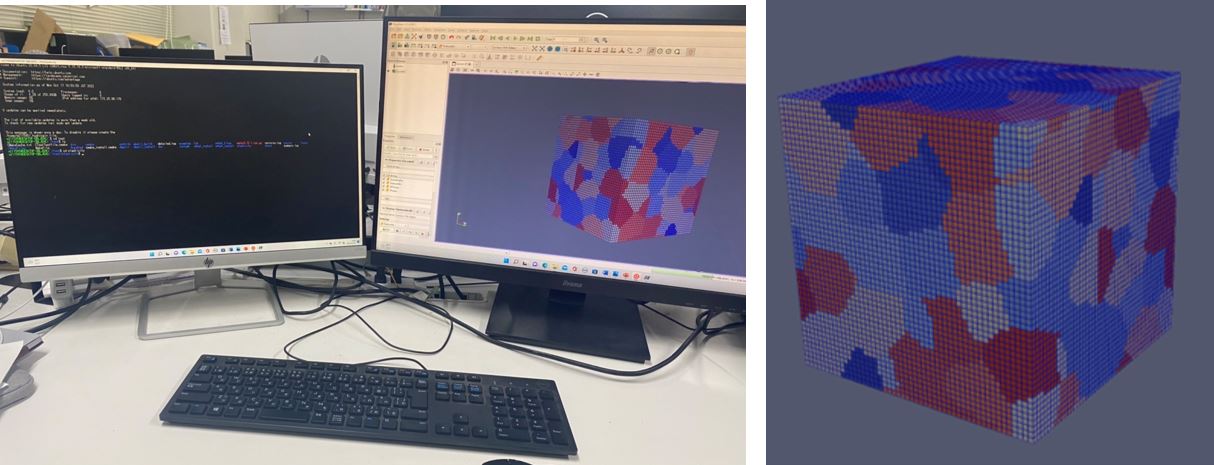

Over the past decades we have been studying the material properties as well as failure characteristics of a wide class of engineering materials, such as structural, bio and smart materials. Our research contributions have focused on the lattice and microstructural mechanisms to make excellent material properties of high strength and high ductility. If you are interesting in Materials Sciences and our research group, please don’t hesitate contact with us.