|

|

|

|

◆ High Pressure and High Temperature Apparatuses |

|

|

Because the Earth's interior is in a condition of high temperature and pressure, Because the Earth's interior is in a condition of high temperature and pressure,

high temperature and pressure apparatuses are needed to study the physical

properties

of the Earth's interior.

There are various types of high temperature and pressure apparatuses.

In our lab, large-volume, multi anvil press apparatuses are installed,

and in particular we focus on the development of Kawai-type apparatuses.

This figure illustrates the principle of the Kawai-type high-pressure

apparatus.

In this system the sample is located in octahedral pressure medium.

Octahedral pressure medium is pressed by 8 cubes with a truncated edge.

These are known as the "2nd stage anvil" cubes, and because

these cubes play

an important role in pressure generation, we simply refer to the 2nd stage anvil

as the "anvil." A truncated edge is referred to as truncation.

Specifically, the 2nd stage anvil, composed of 8 anvils, is pressed

by the 1st stage anvil,

composed of 6 anvils.

The 2nd stage anvil is generally made of super hard materials (tungsten-carbide

(WC) The 2nd stage anvil is generally made of super hard materials (tungsten-carbide

(WC)

bound by a small amount of Co). The maximum pressure strongly depends

on the anvil

material. Further, the maximum generated pressure and sample size are

controlled by

the truncation edge length (TEL). Generally speaking, there is a trade-off

relationship

between the sample size and the maximum generated pressure.

Because the maximum pressure depends on various factors, it is hard to

predict the Because the maximum pressure depends on various factors, it is hard to

predict the

maximum pressure. From our experience, we found the the following to be the

optimum conditions; realizing 41 GPa with TEL=1.5 mm, 34 GPa with TEL=2.5 mm,

30 GPa with TEL=3.0 mm, 25 GPa with TEL=6.0 mm, and 22 GPa with TEL=7.0

mm.

To generate higher pressure, we have to modify the anvil material. To generate higher pressure, we have to modify the anvil material.

Sintered diamond and sintered cubic boron nitride are considered to be harder

materials than WC.

By using sintered diamond anvils, therefore, we can generate pressures

up to 63 GPa.

Heating of the sample is carried out by a furnace in the pressure medium. Heating of the sample is carried out by a furnace in the pressure medium.

In extreme cases, we can generate temperatures of up to 2800˚C.

The temperature is measured by a thermocouple.

|

|

|

|

This picture shows main press of our lab,

a USSA-5000 Kawai-type apparatus, with which we can apply

a maximum press load of 2000 tonf.

Three of the 1st stage anvils are fixed on the upper guide block

and the other three is fixed on the lower guide block.

A set of the 2nd stage anvils is pressed in the direction of [111]

to top and bottom.

The cubic size of the 2nd stage anvil (corresponding to the size

of the 1st stage anvil) depends on the maximum load.

As for the size of the 2nd stage anvil, we generally use anvil

lengths of 26 mm, 32 mm, and 46 mm.

The maximum loads then become 700 tonf, 1000 tonf, and

2000 tonf, respectively.

This apparatus has 2 independent heating systems controlled

by a PC, allowing us to heat the samples using various complicated

methods.

This technique also allows us to synthesize large single crystals.

|

|

|

|

This picture illustrates the USSA-1000 Kawai-type apparatus

with a maximum load of 1000 tonf, which is smaller than that of

the USSA-5000.

The concept is the same as that employed in the USSA-5000,

but the 2nd stage anvil size is limited to 32 mm, and there is

only one heating system.

We use this press for simple sample synthesis and studies of phase

relations.

|

|

|

|

This picture shows the high pressure apparatus UHP-2000/20

with DIA-type guide blocks. The DIA type guide blocks have

4 slopes of 45°.

The sliding blocks advance horizontally, whereas the upper

and lower blocks move vertically. We can generate pressure in the

cubic space surrounded by the top of each guide block and sliding

block.

There are two types of high pressure generation:

1) as a single stage press with a cubic space

(using only 6 anvils), and

2) as a Kawai-type double stage press with an octahedral space

(6-8 system).

When used as a cubic anvil press, we can generate a maximum

pressure of 6 GPa with 15 mm of anvil size.

We generally use this generation to conduct measurements of the

physical properties of rocks.

When used as a Kawai-type apparatus, the 2nd stage anvil is

sintered diamond, and the generated pressure generally reaches

as high as 50GPa. This system is capable of achieving the

conditions

of the lower mantle.

|

|

|

|

In addition, we also have a piston cylinder apparatus.

Using this apparatus, we can conduct petrological experiments

below 3 GPa.

|

|

|

|

|

We also have some high temperature

furnaces for synthesis.

The picture to the left shows a box type

furnace (1500-1600°C).

The picture on the right shows a

cylindrical furnace under controllable

oxygen fugacity.

|

|

|

|

The diamond-anvil cell (DAC) allows us to

generate very high pressure by compressing

materials between two diamond anvils.

Diamond is the strongest known material and

is transparent to a wide range of

electromagnetic radiation, including X-rays,

infrared, and visible light.

Through the 'transparent' window of

diamonds, we can directly observe various

phenomena under extremely high-pressure

conditions.

We use a symmetric-type diamond anvil cell,

as shown in the picture to the left.

|

|

|

|

A new press with six independently moving

cylinders so called a “6-axis” apparatus was

developed (1) to achieve an ideal uniform

compression among anvils and (2) to

minimize frictional loss of applied load in the

guide block.

The movement of the six anvils is monitored

and controlled by the servo system.

Therefore it is possible to keep the cubic

space (ex. Kawai-type high P. cell) within

accuracy of 2 mm during compression and

decompression.

This press is mainly used for the experiments

higher than ~50 GPa.

|

|

|

|

|

|

|

|

|

|

|

◆ Measurement Instruments |

|

|

HACTO has a number of measurement systems to measure the elastic and

electric properties of minerals in our laboratory.

|

|

|

|

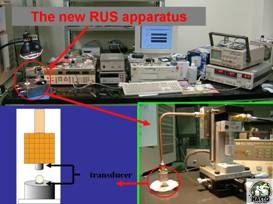

The picture to the left shows a measurement system

for elastic constants by the resonance method.

Elastic constants can be determined with high precision

using this system.

|

|

|

|

This picture shows another system used to measure

elastic properties under high-pressure conditions.

|

|

|

|

The first picture to the left shows an impedance

analyzer, Solartron 1260, which is used to measure

various and complex electric properties of minerals.

For measuring electric conductivity only, this system

should be used in combination with a function generator

and digital multimeters, which are shown in the second

picture on the left.

This system is very functional in high-pressure

experiments because it is resistant to electric noise.

The measurable range is up to 1 giga ohm.

|

|

|

|

|

|

|

|

|

|

|

◆ Analysis Instruments |

|

|

Here we introduce the analysis instruments used for starting and synthesized

materials for high pressure experiments in our HACTO laboratory.

|

|

|

|

A powder X-ray diffractometer |

|

|

|

A micro-focus diffractometer |

|

|

|

This picture shows an electron probe micro analyzer,

JEOL-JXA8800.

This system can analyze elements from boron to lead in a

small area (smallest 5 microns).

|

|

|

|

This picture shows a scanning electron microscope,

which is used to observe the textures of recovered samples

of high pressure experiments.

|

|

|

|

|

|

|

|

|

|

◆ Processing Machines |

|

|

HACTO has various processing machines as accurate high-pressure cell parts are required

to conduct high pressure experiments.

|

|

|

|

|

|

|

|

|

|

The most basic of these are lath,

drilling, and milling machines,

all of which are capable to process

parts with simple features.

If you want to make more complex

parts, numerical-controlled

processing machines are needed.

|

|

|

|

This picture shows a simple automated processing machine,

that is, a small numerical-controlled milling machine.

This is used for easily processed materials such as pyrophillite.

|

|

|

|

|

HACTO also has a more full-fledged machine, i.e.,

a machining center.

12 tools installed in this machine enable the

processing of 2.5-dimensional cell parts as

needed.

|

|

|

|

It is difficult to create more accurate parts using only the drills and

endmills of the machines mentioned above to process materials.

Laser processing, however, can provide more accurate processing.

This picture shows an infrared laser machine processing materials

by laser ablation with a few ten-micron diameter beams.

|

|

|

|

HACTO also has an ultraviolet laser machine for the processing of

materials not processed by infrared, such as noble metals and

white ceramics. |

|

|

|

HACTO has a special machine for processing single crystals,

an ultrasonic ablative machine.

This machine hollows a single crystal with ablative grains shaked

by ultrasonic treatment. |

|

|

|

This picture shows a cutting machine for single crystals

with a blade of 50-micron thickness. |

|

|

|

This picture shows a single-crystal polishing machine. |

|

|

|

This last picture shows a spark eroder for machine sintering

diamond anvils. Sintered diamond is too hard to machine using

a mill, drill, or bite.

In this apparatus, therefore, sintered diamond can be electrically

machined due to the Co binder.

|

|

|

|

Diamond wire saw enables us to cut tiny samples precisely

(ex. high pressure experimental run charges) under a microscope

observation. |

|

|

|

|

|

|